Research

The Sustainable Food Processing group focuses on the following areas:

• Developing and applying multi-indicator sustainability assessments and advanced methods for food systems analysis to gain comprehensive system insights and identify high-impact actions.

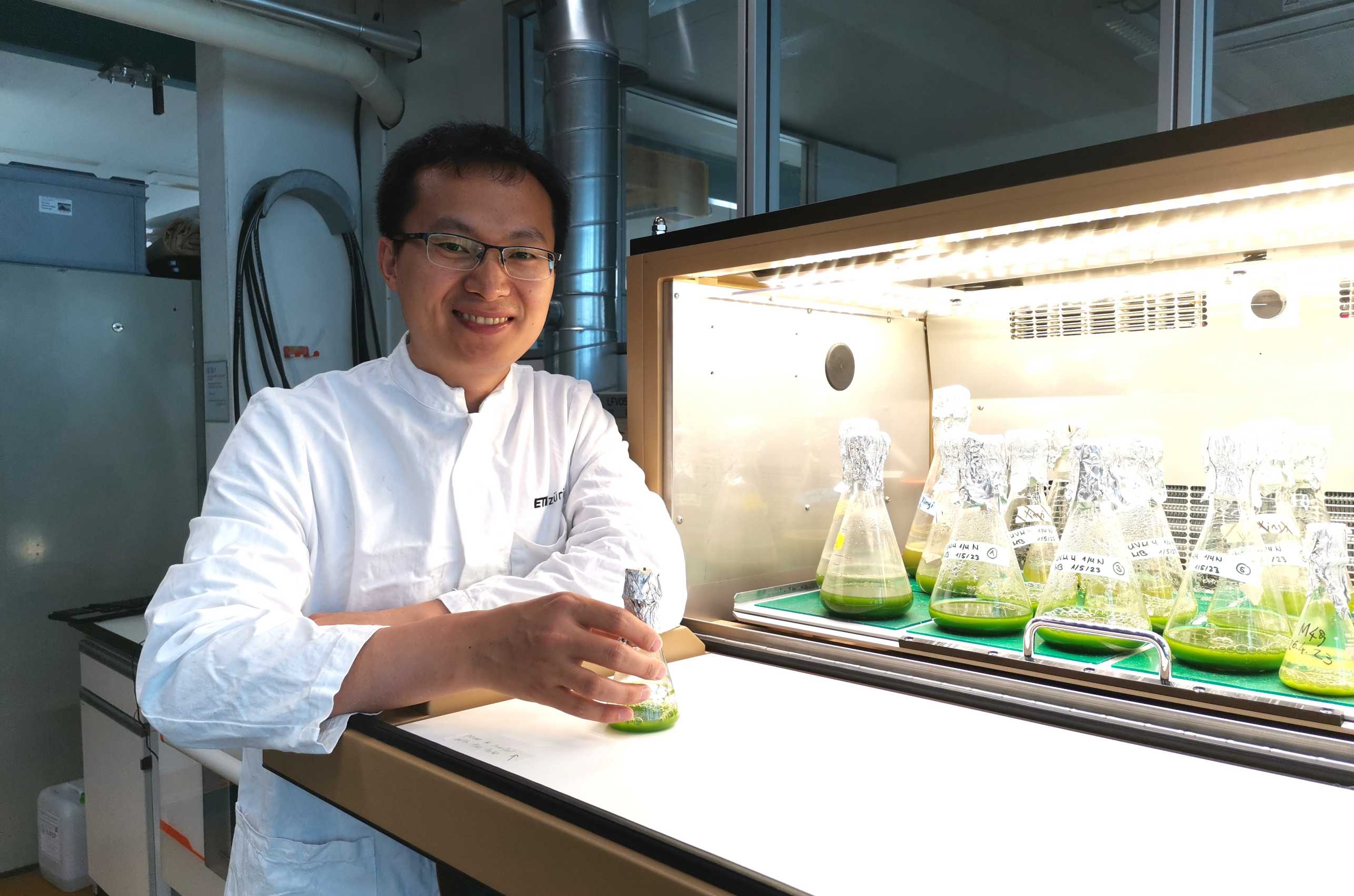

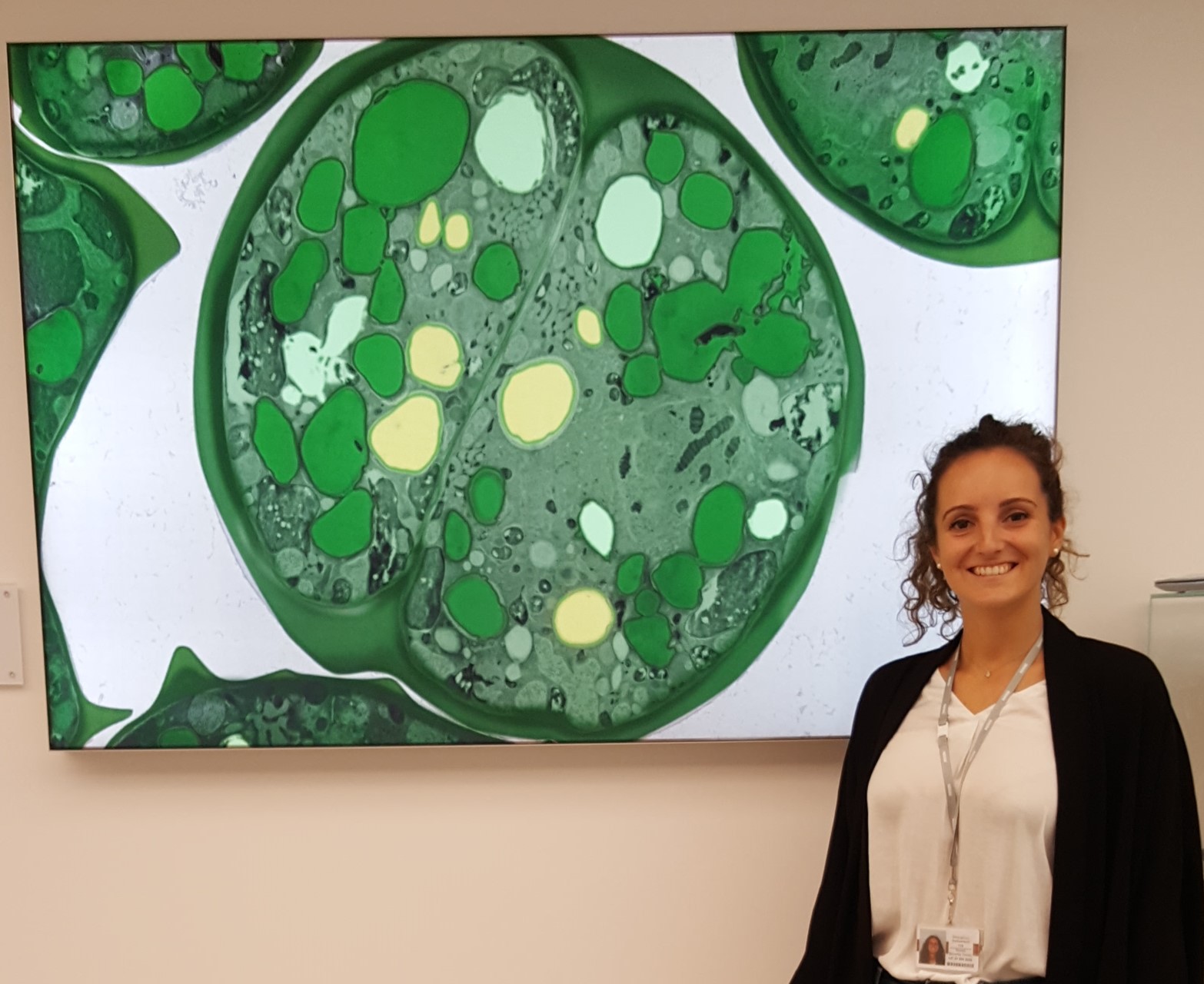

• Conducting microbial ecosystem analysis and controlling microalgae and insect systems during upstream processes.

• Investigating Structure-Process-Property relationships and exploring innovative processing techniques for disintegration, high-quality structuring, gentle stabilization, and the release of functional proteins and value-added ingredients.

• Quantifying the nutritional and health impacts of food innovations through broad in vitro analyses, and linking these findings to targeted in vivo studies in collaboration with the ETH Institute of Food, Nutrition and Health (IFNH).

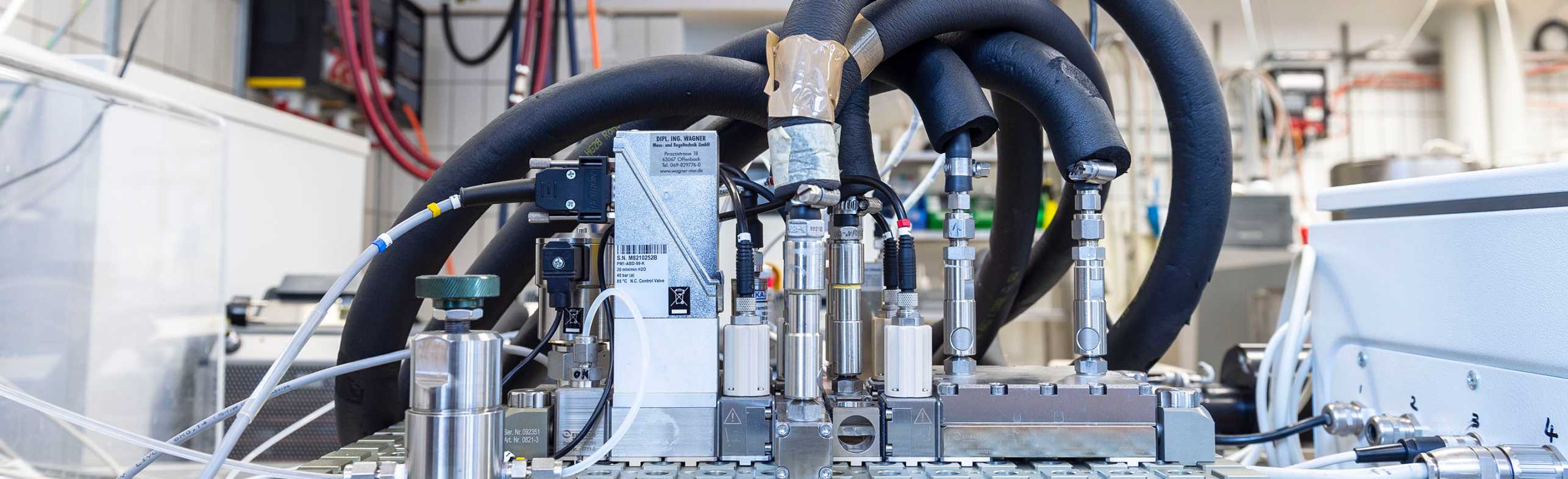

The group operates unique extrusion and pulsed electric field (PEF) pilot plants at lab and pilot scales. We use 16 mm, 30 mm, and 42 mm twin-screw extrusion systems, equipped with or without specialized cooling dies, inline process controls, and gas injection capabilities. Our batch and continuous PEF units offer pulse widths ranging from 2 nanoseconds to 100 microseconds, with pulse amplitudes up to 15 kV. Additionally, we apply a continuous micro-process engineering platform for thermal and mechanical process development at the lab scale, featuring advanced inline and online process controls.

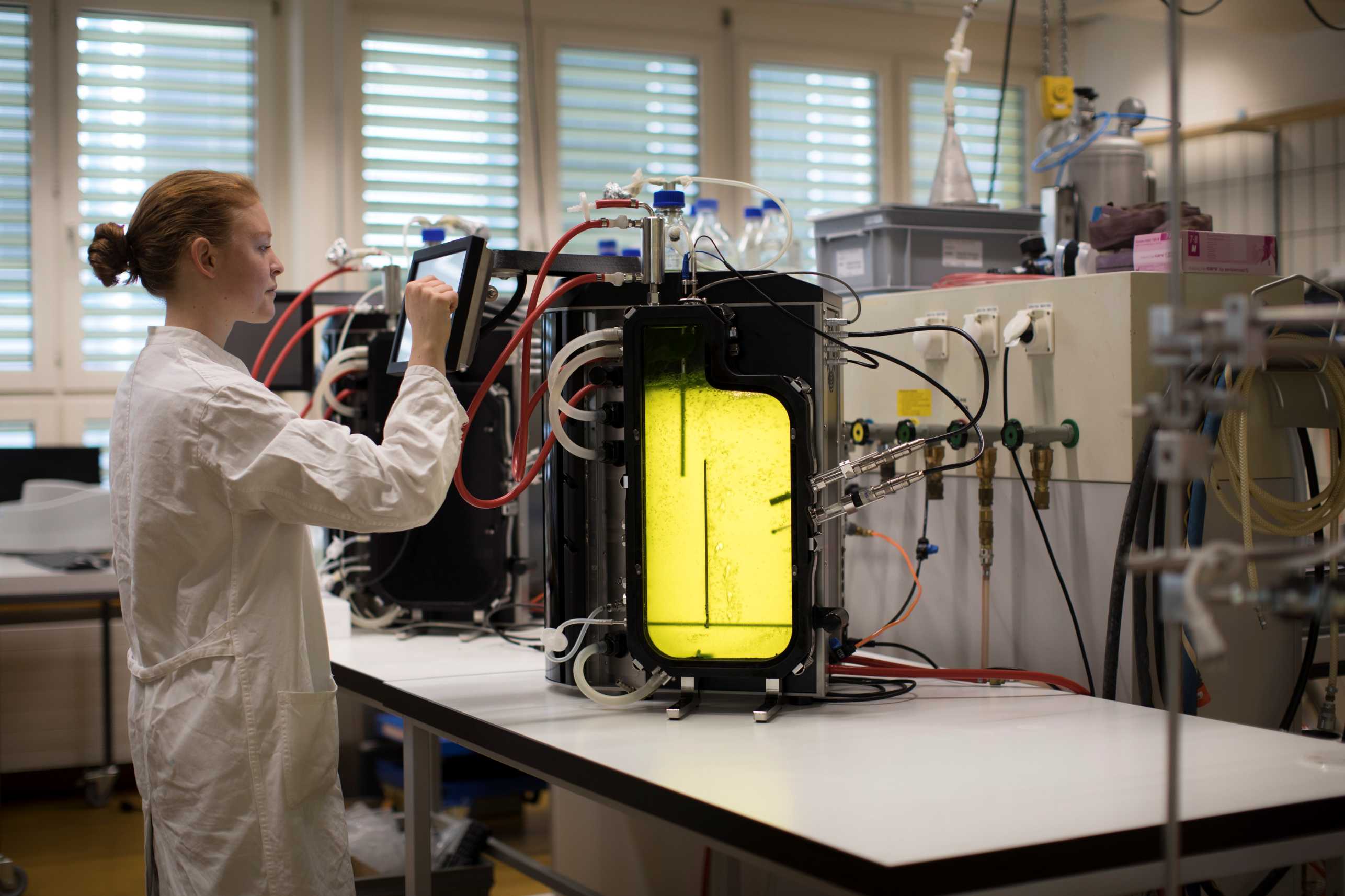

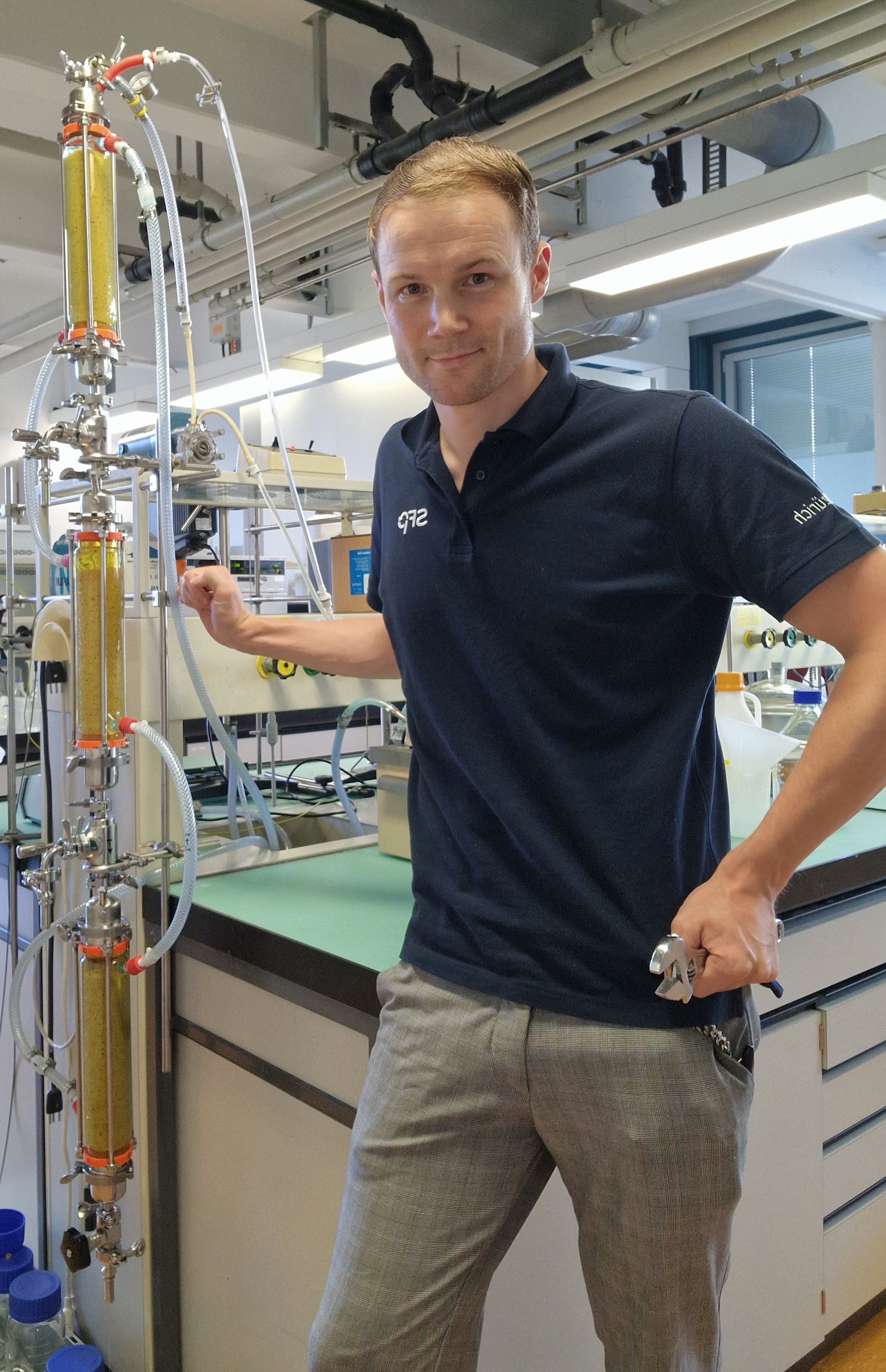

Ultra- and microfiltration systems enable effective fractionation and purification. We are continually developing new microalgae and insect cultivation and downstream processing systems, including a lab-scale black soldier fly larvae colony operated in collaboration with Eawag. For microalgae cultivation, we have advanced equipment such as double flat panel reactors (2 x Algaemist plus 2 x 2 L PBRs), a 5 L fermenter, 2x pilot-scale photobioreactors (25 L & 42 L). Flexible microbial labs with BSL 1 and 2 classification are also available.

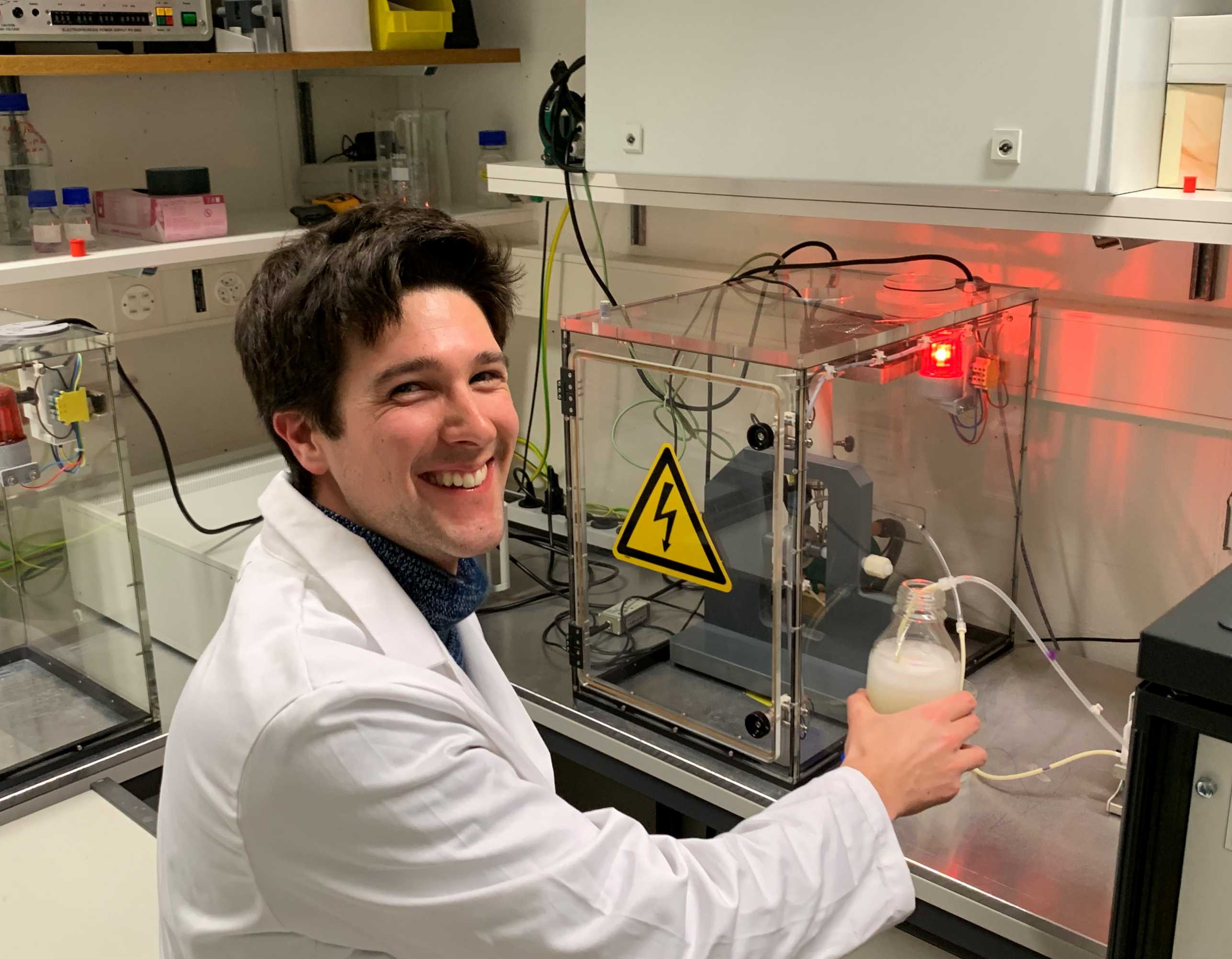

Ongoing equipment development includes batch (up to 1000 MPa) and continuous ultra-high pressure treatment (up to 450 MPa), electroporation for cell disintegration, stress induction, and food preservation, as well as optimization of microalgae reactors.

- Multi-indicator Sustainability Assessment

- Life Cycle Assessment

- Flagship Project Novel Proteins for Food and Feed

- Urban Microalgae-Based Protein Production project at the Singapore-ETH Centre

- Insect Sustainability and Processing

- Black Soldier Fly Larvae Treatment

- Microalgae Biotechnology & Biorefinery

- Comprehensive PEF System Analysis and Microalgae Applications

- Extrusion

- Micro Process Engineering

- Bacterial Spore Mechanisms

- High Pressure Thermal Sterilization

- Low Energy Electron Beam

The ETH Zurich World Food System Center Flagship Project Novel Proteins for Food and Feed aims to develop food innovations to provide new sources of sustainable and nutritious protein for a growing world population.

Find out more about this World Food System Center Flagship Project here:

https://worldfoodsystem.ethz.ch/research/flagship-projects/NovelProteins.html

Some impressions of our running Sustainable Food Processing projects and team: